Hot-Chamber Magnesium Die Casting

Release time:2020-08-07

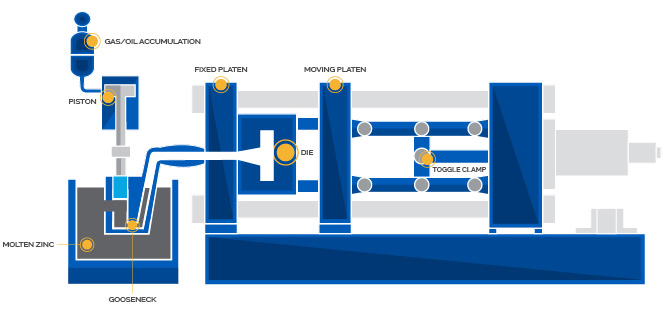

Hot-chamber die

casting can be used with magnesium and other low melting alloys using either our proprietary multi-slide or standard tooling. The hot-chamber process is ideal for metals that don’t readily attack and erode metal pots, cylinders, and plungers.

The operating sequence of the hot-chamber standard die casting process

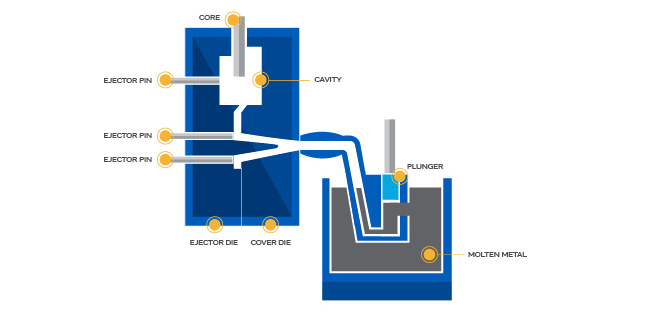

The die is closed and the piston rises, opening the port, allowing molten metal to fill the cylinder.

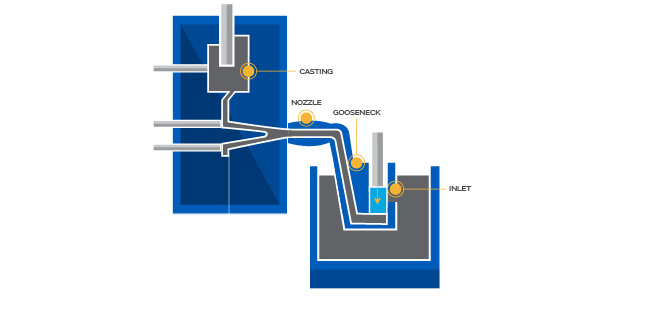

Next, the plunger seals the port, pushing the molten metal through the gooseneck and nozzle into the die cavity where it is held under pressure until it solidifies.

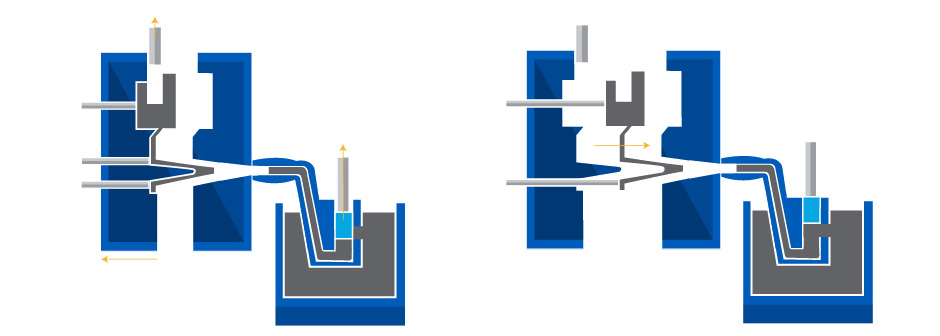

The die opens and the cores, if any, retract. The casting remains in only one die half – the ejector side. The plunger then returns, allowing residual molten metal to flow back through the nozzle and gooseneck.

Ejector pins push the casting out of the ejector die. As the plunger uncovers the filling hole, molten metal flows through the inlet to refill the gooseneck.