The advantages of die casting materials in modern manufacturing!

Release time:2023-09-23

The advantages of die casting materials in modern manufacturing!

In modern manufacturing, the choice of materials plays a crucial role in the performance and quality of products. As a commonly used metal material, die-casting material plays an important role in various fields because of its unique advantages .

** High strength **

Die casting materials usually have excellent strength and rigidity and are able to maintain stable performance under different stress conditions. This gives die casting materials a distinct advantage in the manufacture of highly demanding parts, such as automotive engine parts, industrial machinery components, etc. Its high strength characteristics provide a strong guarantee for the reliability and durability of the product.

** Lightweight **

Compared with other metal materials, die casting materials have a lower density, so the lightweight design of the product can be achieved. In the automotive, aerospace and other fields, lightweight is a key strategy for the pursuit of high efficiency and energy conservation and environmental protection. By choosing die casting materials, the product not only maintains sufficient strength, but also reduces overall weight and improves performance.

** Complex shape forming **

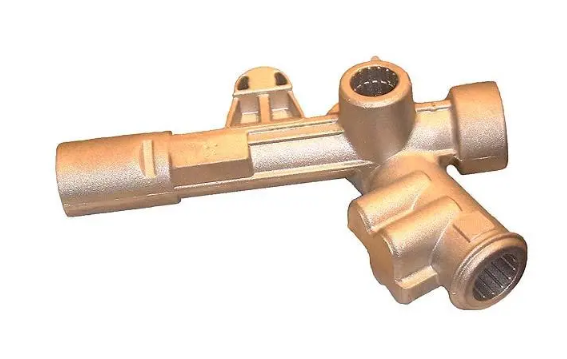

Die casting technology can accurately inject metal materials into the mold to achieve high precision molding of complex shapes. This makes the die-cast material suitable for the production of parts with complex geometrics-such as connector housings, electronic device housings, etc. Its precision molding features provide more creative space for product designers.

** Excellent thermal conductivity **

Some die-casting materials have excellent thermal conductivity, which can effectively conduct heat and achieve rapid heat dissipation of parts. This makes die-casting materials widely used in radiators, engine housings and other fields, improving the thermal management efficiency of products.

** Environmentally sustainable **

Modern manufacturing is increasingly focused on environmental protection and sustainable development. Die casting materials are usually metal materials that can be recycled, in line with the concept of environmental protection. Its production process is relatively efficient, reducing energy and resource consumption and reducing the environmental load.

In summary, die-casting materials play an important role in modern manufacturing due to their high strength, lightweight, complex shape forming ability, excellent thermal conductivity and environmental sustainability. As a versatile metal material, die casting materials are constantly innovating, bringing new possibilities and opportunities for product design in various fields, providing the perfect solution for the fusion of light and strong.