What is the hardness of aluminum alloy die casting?

Release time:2023-12-19

What is the hardness of casting-china.com' target='_blank'>aluminum alloy die casting?

In addition to stainless steel, aluminum is the most commonly used metal in production and life, and it is widely used in different industries. From decorations to mechanical parts, and even aircraft, ships, automobiles, communications equipment, home appliances and various equipment, aluminum is also widely used in the construction industry. The reason why aluminum is popular is that it has many characteristics that other metals do not have, such as light weight, high strength, low melting point, good ductility, water resistance and rust prevention, and low price. Another reason for its popularity is its strong flexibility, which can add other metal elements to produce various alloys with different properties, such as magnesium aluminum alloy, copper alloy, zinc alloy, manganese alloy and so on. Aluminum alloy density is low, but the strength is relatively high, close to or more than high-quality steel, good plasticity, can be processed into various profiles, with excellent electrical conductivity, thermal conductivity and corrosion resistance, widely used in industry, the use of second only to steel.

Aluminum alloy is divided into two categories: cast aluminum alloy and deformed aluminum alloy

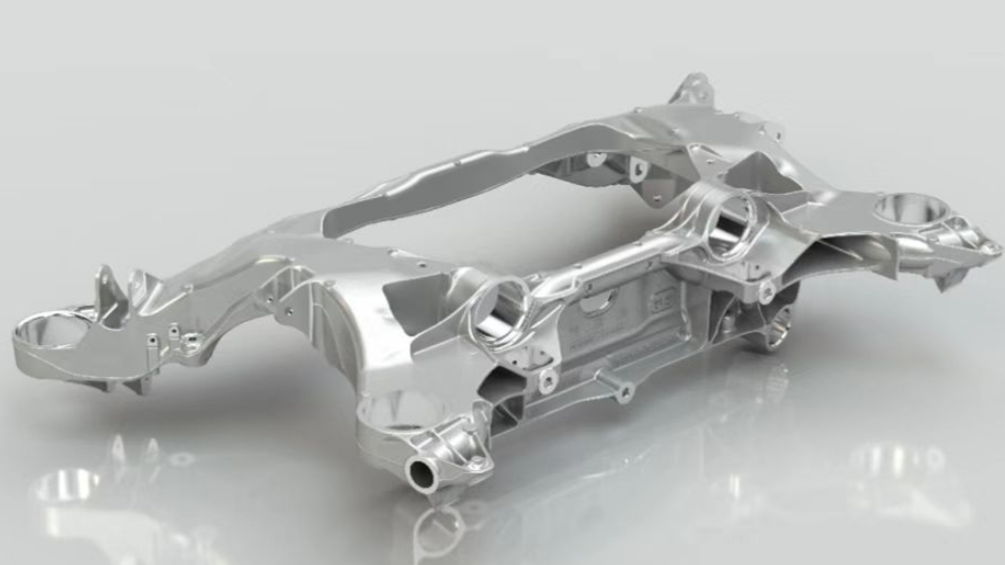

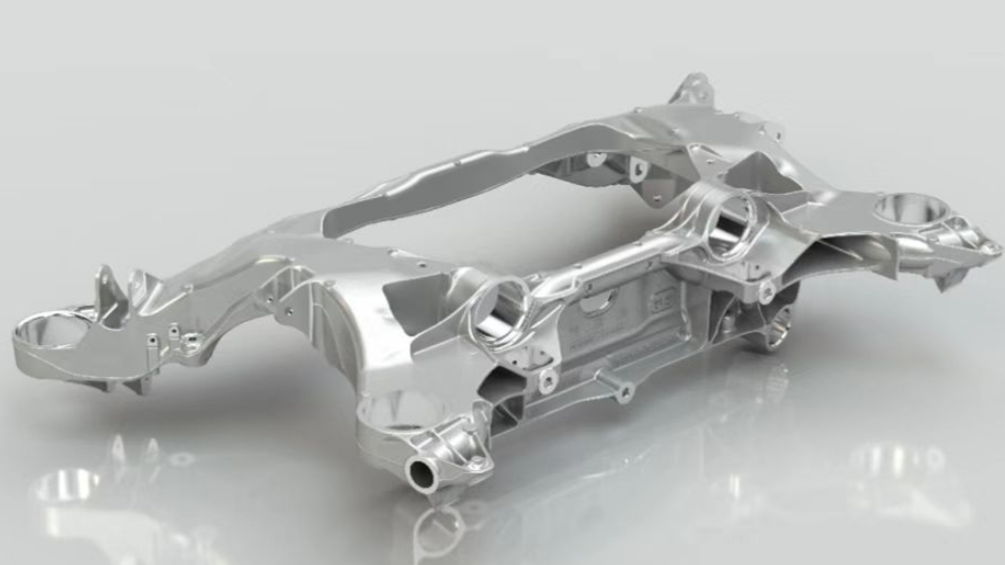

Casting aluminum alloy is an aluminum alloy filled with aluminum alloy solution to obtain the blank of various shapes of parts. It has the advantages of low density, high specific strength, good corrosion resistance and casting process, and little restriction by the structural design of parts. Most require heat treatment to strengthen the alloy, eliminate the internal stress of the casting, stabilize the structure and part size. Cast parts are widely used in production and life.

Deformed aluminum alloy is an aluminum alloy whose structure and shape are changed by stamping, bending, rolling, extrusion and other processes. Molten ingot, then subjected to metal plastic deformation processing, to make various forms of aluminum alloy. Heat treatment can strengthen aluminum alloy: including hard aluminum alloy, super hard aluminum alloy, forged aluminum alloy; There are also aluminum alloys that cannot be strengthened by heat treatment, mainly various rust-proof aluminum alloys. It is widely used in aviation, automobile, shipbuilding, construction, chemical industry, machinery and other industrial sectors.

The hardness of aluminum alloy castings is often determined by the other metal elements added to it, different alloy hardness is different, among them, the highest hardness is 7 series of aluminum zinc alloy, hardness is HB150, followed by 6 series of aluminum magnesium silicon alloy, T6 aging hardness is HB90-110, is also a more widely used aluminum alloy. The alloy of Series 5 is aluminum-magnesium alloy with hardness between HB45-75. 4 series of aluminum-silicon alloy HB80. The hardness of the 3-series aluminum-manganese alloy is between HB35-45, while the hardness of the 2-series aluminum cylinder alloy is HB120-145.1 series pure aluminum alloy is HB30-45.

Aluminum alloy labels used in Ustar die casting

The aluminum alloy used in Ustar die-casting is the national standard YL113, the Japanese brand ADC12, and the US number A384, which is an aluminum-silicon-copper alloy, among which there are a small amount of other metals. YL113 aluminum alloy is a widely used material in the die-casting industry, it is very stable at high temperatures, the possibility of cracks is very small, and its corrosion resistance is very high. Long service life, it is light weight, good fluidity, easy to cast, it also has excellent mechanical and thermal properties, with good dimensional stability. It is often used in electronic equipment, motor vehicle parts, home appliances, power tools, communication equipment, electric vehicles and other parts manufacturing, and has a very wide range of applications.

Die casting of aluminum alloys enables the production of complex parts that cannot often be machined or extruded. Such as engine blocks, transmission components and other complex parts. In addition, medical devices and medical equipment such as the need for precision and precision components, aluminum alloy die casting can effectively meet this demand. Outdoor lighting and telecommunications industries need to be exposed to wind and rain in the outdoors for a long time, then the excellent rust prevention ability of aluminum alloy die casting can solve such problems. Industrial equipment such as air compressors and pumps are mostly made of die-cast aluminum.

In terms of products, take cast aluminum furniture as an example, how to reflect the hardness? Standing in the consumer position, is the load-bearing capacity, is the robustness and durability.

In terms of load-bearing capacity, the cast aluminum chair produced by Ustar, although the weight is only 8 kg to 10 kg, but the load-bearing capacity is more than 300 kilograms. And the structure is stable, durable without deformation, appearance without change, so that people fully feel the hardness and support of aluminum alloy die casting.

The excellent hardness index of the product brings more confidence and reliability to the user.