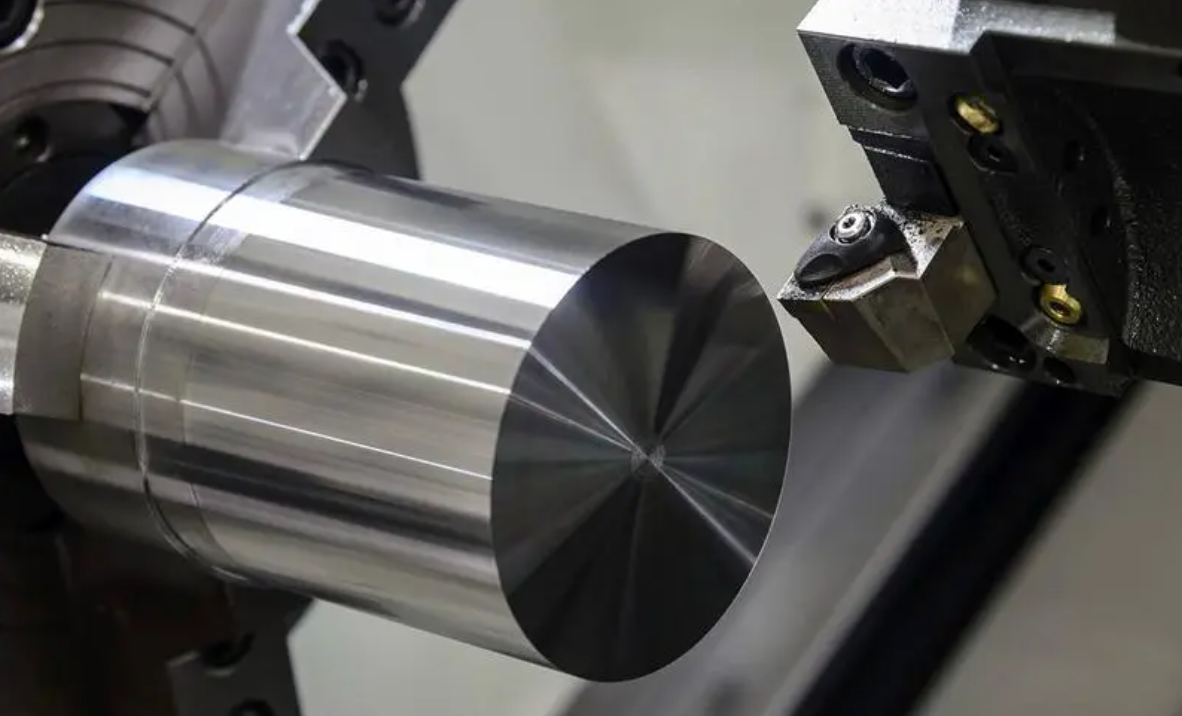

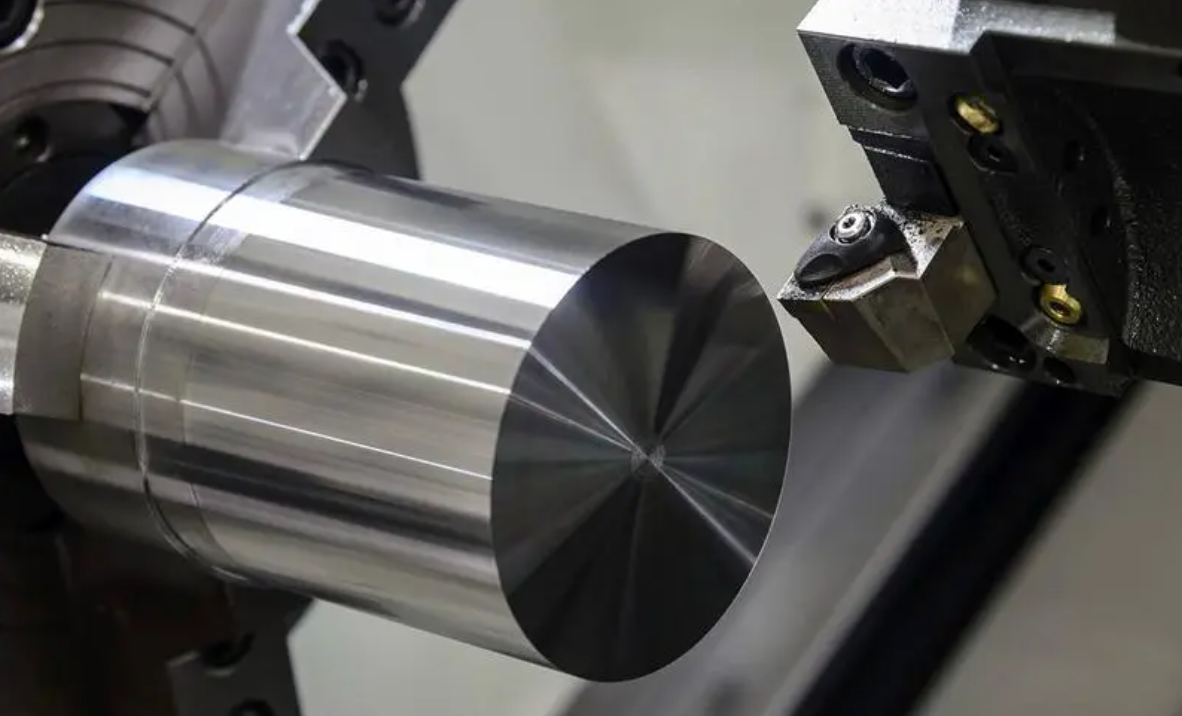

Stainless steel cnc machining how to ensure processing efficiency and productivity?

Release time:2024-03-21

Stainless steel machining-sz.com' target='_blank'>cnc machining how to ensure processing efficiency and productivity?

In stainless steel cnc machining, ensuring machining efficiency and productivity is of Paramount importance. Stainless steel materials usually have high hardness and high ductility, which puts higher requirements on machining equipment and process flow. Here are some key factors that can help machining companies ensure high efficiency and productivity in stainless steel cnc machining .

Select the appropriate cutting process parameters: In stainless steel cnc machining, it is very important to choose the right cutting speed, feed speed and cutting depth. Reasonable cutting process parameters can maximize the use of machining equipment performance, improve processing efficiency and productivity. In addition, it is also necessary to select suitable cooling lubricants for different processing processes and different tools to improve processing efficiency.

Rational planning of tool paths: well-designed tool paths can reduce overlap and idling of cutting paths and improve cutting efficiency. With intelligent CAM software, the tool path can be optimized, the machining time can be reduced, and the unnecessary cutting load can be reduced, thus improving the production efficiency.

The use of modern equipment: Investment in advanced cnc machining equipment, such as high-speed cutting center (HSC), five-axis machining center, etc., can improve the speed and accuracy of stainless steel CNC machining. Modern equipment usually has higher cutting speed and machining accuracy, and can complete machining tasks faster.

Optimize fixed clamping and tool change: Fast and reliable clamping systems and efficient tool change systems reduce line downtime. Effective tooling design and tool management can reduce downtime in the production process and improve production efficiency.

Quality tool and equipment maintenance: Ensure timely replacement and maintenance of tools, as well as regular maintenance of equipment, can maintain the best performance of the machine equipment, avoid unnecessary downtime and maintenance time, and ensure the stability and reliability of the processing process.

In short, the high efficiency and productivity of stainless steel cnc machining need to rely on scientific and reasonable process parameters, appropriate equipment and tools, optimized tool path and other factors. Machining manufacturers need to consider the factors of process technology, equipment selection and management to ensure the best processing efficiency and productivity in the stainless steel cnc machining process.