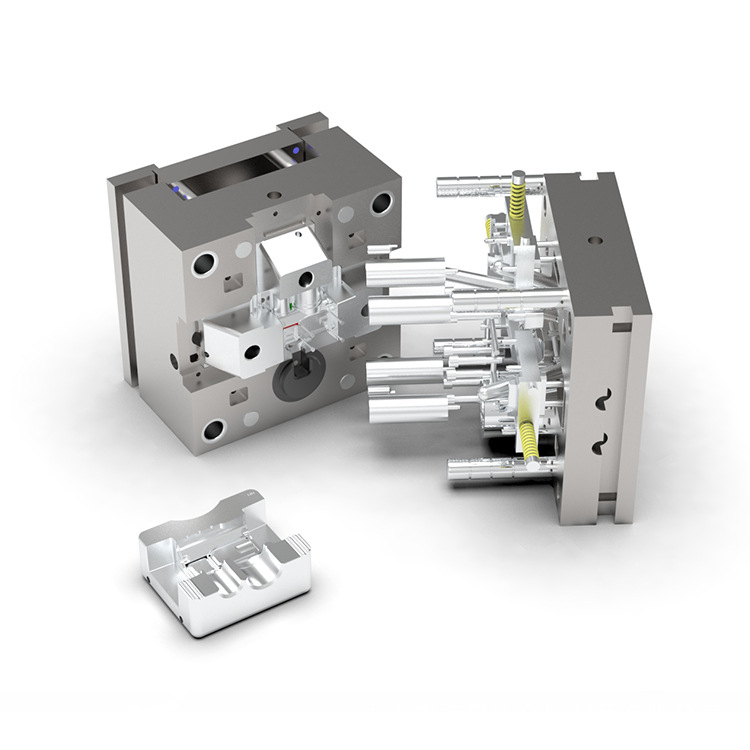

It is a major investment to custom a complete function production die. So a prototype die is usually for a small amount of parts in order to test the components in many different conditions. 3D printed parts, machined hogouts, or gravity castings are belonging to prototyping strategies. However, these all need to consider tradeoffs on the design, tolerances, and properties. If you want the same properties, alloy, geometry and process, high pressure die casting prototype die is a great choice.