Cold-Chamber Die Casting

Release time:2020-08-07

Cold-chamber die

casting is ideal for metals such as aluminium which have a high melting point. During this process, metal is liquefied in a furnace at extremely high temperatures and then ladled into a cold chamber to be injected into the die.

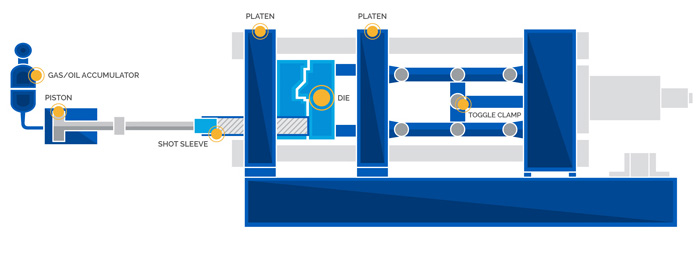

The basic components of the cold-chamber die casting machine

During cold-chamber die casting, the molten charge, which consists of more material than is required to fill the casting, is ladled from the crucible into a shot sleeve where a hydraulically operated plunger pushes the metal into the die. The extra material is used to force additional metal into the die cavity to compensate for shrinkage, which takes place during solidification.

The main components of a cold-chamber die casting machine are shown below.

Injection pressure of over 10,000psi or 70,000KPa can be obtained from this type of machine.

Operating sequence of the cold-chamber die casting process

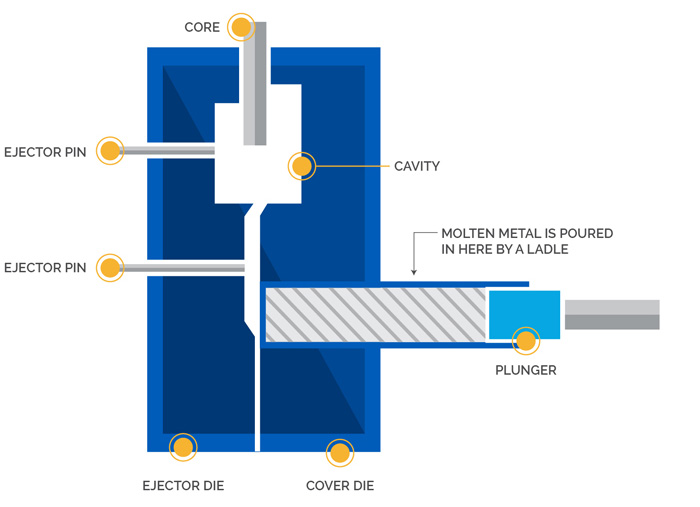

The die is closed and the molten metal is ladled into the cold-chamber shot sleeve.

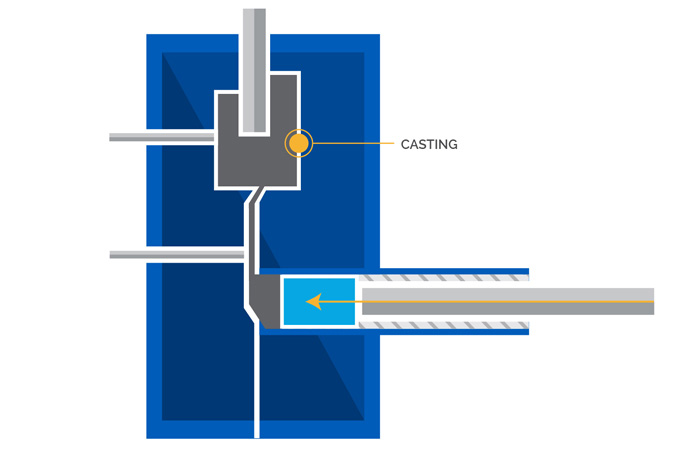

The plunger pushes the molten metal into the die cavity where it is held under pressure until it solidifies.