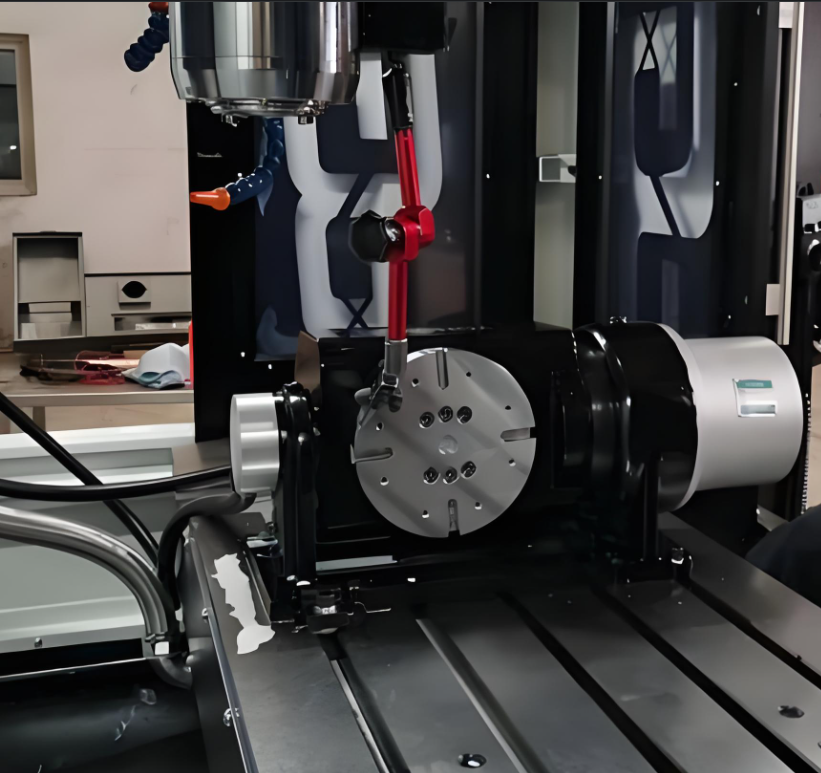

What is 5-axis 3+2 machining? Whats 3+2? 3+2 is three axes plus two axes to achieve five axes 3+2, with and without the tool point to follow, and then with the tool point to follow is able to achieve five axes and five linkage, without the tool point