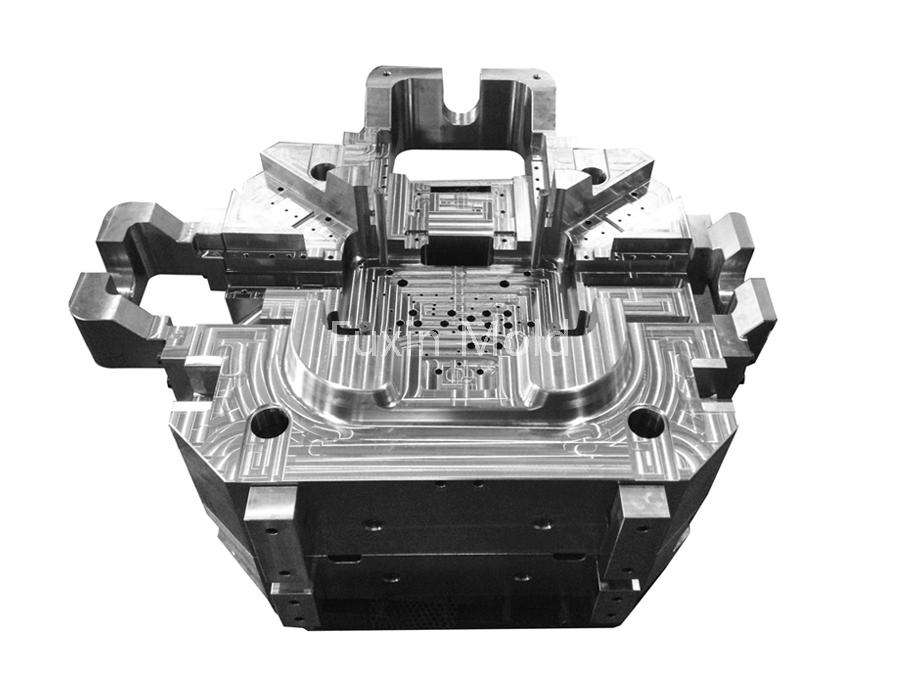

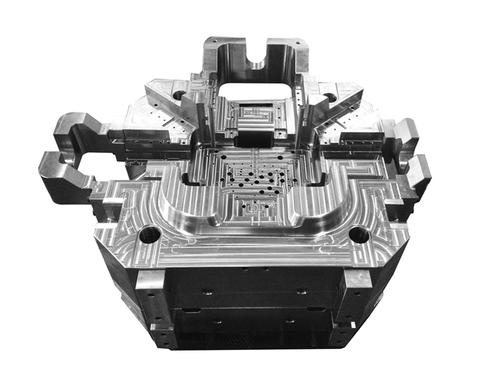

Die casting is a manufacturing process that involves production of geometrically complex parts using molten metal and reusable die casts. A simple and highly cost-effective process, die casting has been one of the most important reasons for the industrial revolution. In this manufacturing process, a die casting design is first created based on the size, shape and function of the final produced part. After the design is created, the non-ferrous metal perfect for the procedure will be chosen. The properties of the metal will be taken into serious consideration as it will affect the design and construction of the finished die casting parts.