Development and application of vacuum die casting technology for aluminum alloy

Release time:2023-09-08

Development and application of vacuum die casting technology for casting-china.com' target='_blank'>aluminum alloy

In recent years, the global environment has been seriously damaged. The emergence of greenhouse effect has raised people's awareness of environmental protection and opened the idea of finding new resources. At present, a large number of advanced technologies and environmental protection technologies are applied in enterprises. In the developed countries, the development and application of vacuum die casting technology of aluminum alloy has been widely concerned. For a long time, in order to expand the application range of aluminum alloy vacuum die casting technology, people continue to develop some new special die casting methods. The application of aluminum alloy vacuum die casting technology has improved the production efficiency of enterprises and brought huge benefits to enterprises.

1 Vacuum die casting technology

1.1 Overview of vacuum die casting technology

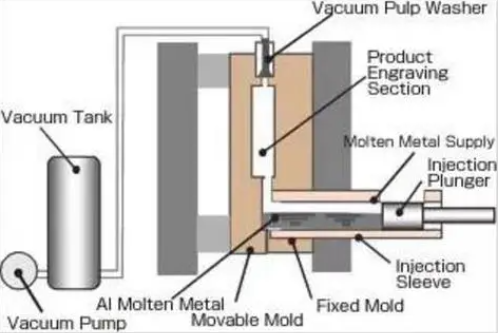

Vacuum die casting technology mainly refers to the advanced technology of eliminating or reducing the gas in the die casting mold cavity by pumping the gas in the die casting process, so as to improve the mechanical properties of the die casting and its surface quality. Vacuum die casting technology is mainly divided into two types. One is to pump air directly from the mold. The other is to place the mold in the empty box directly pumping gas. In the aluminum alloy vacuum die casting technology, the position and area of the die exhaust channel are very important. When the area of the exhaust duct is greater than the critical area, the effect of aluminum alloy vacuum die casting technology will be very obvious.

1.2 Characteristics of vacuum die casting technology

Compared with traditional die casting technology, aluminum alloy vacuum die casting technology has its own unique characteristics. First of all, aluminum alloy vacuum die casting technology can reduce or eliminate the porosity in the die casting, greatly reduce the porosity, improve the surface quality of the die casting. Secondly, the vacuum die casting technology of aluminum alloy improves the filling conditions, makes the microstructure of the castings small, improves the hardness of the castings and can die casting relatively thin castings. Finally, the mechanical properties of aluminum alloy castings are improved by vacuum die casting technology. The improvement of this performance makes the vacuum die casting technology of aluminum alloy more simple and convenient in the process and operation, but also has the same efficiency as the ordinary die casting method. However, the mold structure of aluminum alloy vacuum die casting technology is complex, and the installation is difficult. In addition, if the aluminum alloy vacuum die casting technology is not properly controlled, the expected effect will not be achieved. These are the shortcomings of aluminum alloy vacuum die casting technology, therefore, aluminum alloy vacuum die casting technology needs to be further developed.

2 Development of vacuum die casting technology for aluminum alloy

2.1 Aluminum alloy vacuum die casting vacuum stop valve

The vacuum stop valve for aluminum alloy vacuum die casting is mainly connected by the lever principle, and the exhaust channel is closed by the inertial impulse force of the metal liquid. At the beginning of the aluminum alloy vacuum die casting process, the aluminum alloy vacuum die casting mold is closed, and the vacuum valve pushes the lever to compress the spring, so that the vacuum stop valve can be unlocked. When the metal liquid enters the mold, at this time, the metal liquid will use the inertia force to push the piston. When the die casting is completed, the aluminum alloy vacuum die casting mold is opened so that the vacuum stop valve can be opened and returned to the original position and locked. The use of the lever in the vacuum stop valve can improve the sensitivity of the vacuum stop valve and make the function of the vacuum stop valve more reliable.

2.2 Vacuum system for aluminum alloy vacuum die casting

The vacuum degree in the die cavity of aluminum alloy vacuum die casting system reaches more than 91KPa during die casting. And the pumping speed of the vacuum system is very large, and the gas in the mold cavity can be extracted in a very short time. In the vacuum system for aluminum alloy vacuum die casting, the volume of the buffer tank is very large, and the gas in the mold cavity can be extracted in the vacuum and reach the vacuum degree required by the aluminum alloy vacuum die casting technology. Finally, the gas in the buffer tank is extracted by the vacuum pump.

2.3 Sealing method of aluminum alloy vacuum die casting mold

The sealing of aluminum alloy die casting mold determines the intake volume in the vacuum system. The fixed roof seal plate is placed behind the aluminum alloy vacuum die casting mold moving die plate, and the sealing groove and buffer gas groove are set up, and then the heat resistant seal ring is installed in the sealing groove, and the buffer gas groove is installed in the sealing groove between the plate and the cushion plate. When there is a gas leak in the sealed tank, the buffer gas tank can be extracted in time, improve the intake of vacuum system in aluminum alloy vacuum die casting technology, and ensure that the vacuum degree in aluminum alloy vacuum die casting reaches a certain height.

3 Application of vacuum die casting technology of aluminum alloy in automobile industry

With the rapid development of China's economy, car has become the most important means of transportation for People's Daily travel. Although the production of cars has brought great convenience to People's Daily life and work, the burning of fuel by cars has emitted a lot of pollutants. The application of automobiles not only uses a lot of energy, but also pollutes the environment. Therefore, the current automotive industry must move towards green and lightweight development in order to reduce the use of energy while protecting the environment.

The application of vacuum die casting technology of aluminum alloy in automobile industry can meet the requirements of lightweight and green automobile. The use of aluminum alloy vacuum die casting technology in auto parts can make the automobile have better corrosion resistance, and the use of aluminum alloy vacuum die casting technology of auto parts has high productivity. In recent years, in order to adapt the modern automobile industry to the market competition, the development of aluminum alloy vacuum die casting technology should be stable and the composition can be well controlled. In addition, automotive parts with aluminum alloy vacuum die casting technology should be continued to be developed and used to improve the market competitiveness of the automotive industry, and accelerate the application of aluminum alloy vacuum die casting technology in the automotive industry.