Very practical! Causes of sand holes on the surface of aluminum die casting parts and effective solutions .

Release time:2023-10-05

Very practical! Causes of sand holes on the surface of casting-china.com' target='_blank'>aluminum die casting parts and effective solutions .

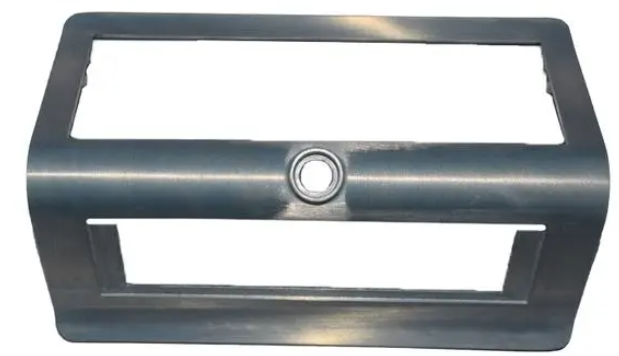

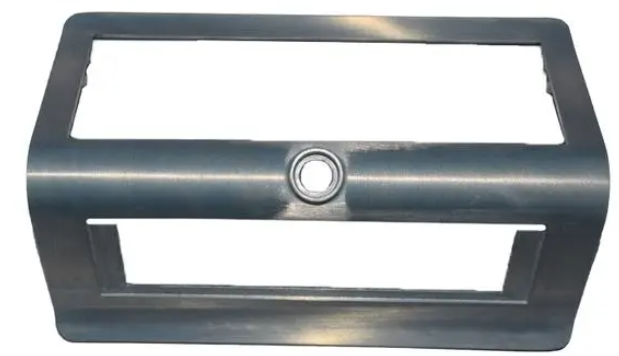

In the process of die casting production, which aluminum die casting surface sand quality problems are often occurred, many simple reasons sometimes have a great impact on the consequences, the damage is larger, Jiawei metal engineers listed in this defect abnormal analysis, for aluminum die casting related production personnel to learn together! Sand hole is a common name for the "hole" defect in the mechanical processing of the internal die-casting parts, mainly manifested as sand hole and slag hole two types.

First, general sand holes (also called sand holes)

In the whole process of zinc die casting production, aluminum die casting surface sand holes will be produced for various reasons, and the main characteristics of sand holes show different regular precipitation sand holes due to different causes.

The causes of sand holes on the surface of aluminum die casting are as follows:

1. Alloy melting time is too long, heat preservation for a long time, resulting in inspiratory oxidation

2. The alloy material is polluted, and the moisture causes H2O to enter the charge

3. The clearing agent itself is damp and enters the alloy liquid

4. The return charge has been seriously corroded, and the surface has become AL (OH) 3

5. Improper mixing in the smelting process leads to more gas entering the alloy liquid

6. The raw material all gold ingot contains too much H

Preventive measures, in view of the above causes, can be the following measures to prevent

1. The alloy must be baked before melting, and the water that can enter the alloy liquid in the furnace must be completely removed to prevent the increase of (H);

2. All tools in contact with the alloy liquid must be baked, coated evenly, and dried;

3. The alloy material is well protected, can not be rained and damp, to prevent the accumulation of a large amount of AL (OH) 3 on the surface;

4. Control the raw materials and strictly control the gas content in the alloy ingot;

5. Strictly control all kinds of oil and dirt into the alloy to prevent (H) from increasing;

6. During the process of alloy refining and degassing, pay attention to the smooth stirring, and the slag removal agent should be moisture-proof at ordinary times to prevent the increase of water vapor.

Second, immersion sand hole

The following is the cause analysis of sand holes on the surface of immersion aluminum die casting:

1. The mold cavity wall contains volatile substances

2. The inner surface of the mold cavity has incomplete volatilized water, release agent, etc. When the alloy liquid is filled during die casting, the volatilized white gas has nowhere to go and is immersed in the casting

Immersion aluminum die casting surface sand hole prevention measures:

1. The release agent should be used appropriately, evenly, not to make local excess and to volatilize clean;

2. The blowing should be uniform and thorough, and there should be no residual liquid on the surface of the cavity;

3. Must not let the cooling water leak into the mold cavity.

Third.,Involved sand holes

Defect characteristics: In the process of aluminum pouring, injection and filling, the gas is involved or contained in the liquid aluminum alloy. With the filling process, the alloy still has eddy spatter, etc., and the gas cannot be eliminated, resulting in the gas in the alloy remaining in the casting as it solidifies to form sand holes. The inner wall of the sand holes is smooth and smooth, but not smooth, there are obvious traces of contamination or corrosion, and sometimes even odor. Sometimes it can be seen that there is a dispersed distribution in the hole such as oil (punch oil)

Discovery method: Appearance inspection or X-RAY after machining

Cause analysis of sand holes on the surface of involution aluminum die casting:

1. Improper opening of pouring system

1. The gate is too thin

2. The material pipe is too large and the filling rate is too low

3. The impact is too intense

4. Gate opening direction is wrong

5. Vortex intensification

6. Improper opening of exhaust system

7. Poor exhaust

8. The overflow groove exhaust groove is improper

9. The vacuum runner is not smooth

2. The amount of oil used in the punch is too much, resulting in combustion after pouring the alloy, resulting in a large amount of smoke

3. The filling speed is too fast, causing a large amount of gas to be involved, or too early to block the exhaust channel

4. The vacuum system leaks, reducing the vacuum effect, because the gas in the high-speed filling cavity can not be discharged

5. Machining allowance is too large

6. Deep cavity gas is closed and cannot be discharged

Preventive measures:

1. Change the direction of metal liquid entering the cavity, and give priority to filling the deep cavity;

2. Properly reduce the injection speed;

3. Under the condition of ensuring good filling, the larger the section at the entrance of the inner gate, the better;

4. The position of the exhaust groove should not be blocked by the alloy liquid flowing into the cavity first, or the overflow groove should be added appropriately, and the external vacuum casting deep cavity can be inserted mold to facilitate gas discharge;

5. Appropriately reduce the amount of punch oil to reduce the occurrence of gas in the material pipe;

6. Increase the charge rate;

7. Correct use of vacuum device, no air leakage;

8. Reduce processing allowance.