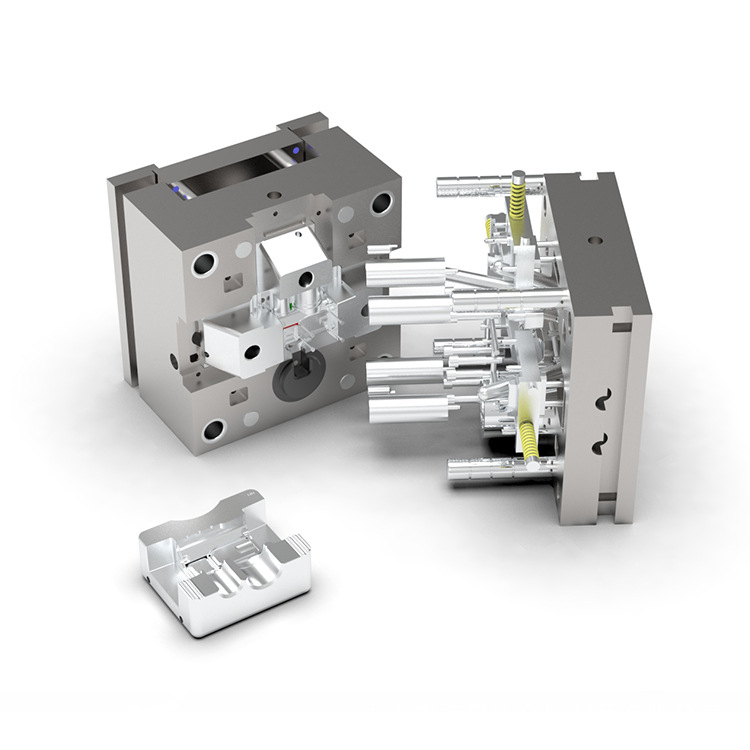

The color EPD surface treatment is a suitable for applying different colors on metal materials and products. As a one-stop die casting company, Junying is offering Color Electrophoresis Metal Finishing Services for aluminum alloy die castings, zinc alloy die casting parts, and other metal products. We can customize a wide range of electrophoresis colors based on your requirements, achieve high corrosion resistance and good protection. With nearly 20 years of experience on CNC manufacturing, mold making and castings production, not only we can produce custom metal casting supplies in complex shapes with high accuracy and affordable prices, but also provide high-quality surface treatment like electrophoresis services to improve the appearance and properties of your aluminum casting products. Fast delivery within a week, welcome to send your files or needs to us, free quotes will be send back as soon as possible.