How should steel casting manufacturers choose the process parameters of sand casting?

Release time:2023-10-09

How should steel casting manufacturers choose the process parameters of sand casting?

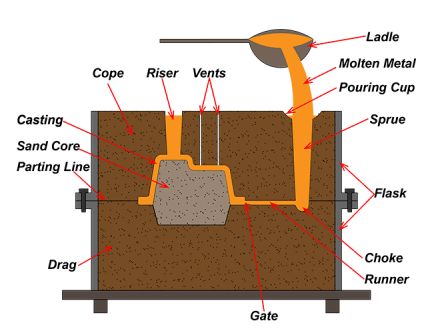

Sand casting refers to a method of producing castings in sand mold, sand casting is generally composed of sand and core sand, sand and core sand are mixed with silica sand and clay or binder material and water in accordance with a certain proportion, sand and core sand to have "one strong three characteristics", the "one strong three characteristics" refers to strength, permeability, concessions and fire resistance. For steel casting manufacturers, sand casting is the most widely used casting method in our actual production.

In the sand casting, casting steel casting manufacturers to choose the subsequent process parameters, in order to draw the casting process diagram, after the casting process plan is initially determined, we must also choose the machining allowance of the casting, shrinkage, mold and core head size, mold inclination and other process parameters.

First, the smallest casting hole and machining margin required by the manufacturer:

(1) Machining allowance: that is, when the technical personnel are designing the casting process diagram, the thickness of the metal layer that needs to be cut is reserved for the casting. The specific value of the machining allowance required in general depends on the variety of alloy, the size of the casting and the casting method.

(2) The smallest casting hole: whether to cast holes and slots on the casting, this depends on the possibility of the process, but also consider its necessity, because generally relatively small holes and slots do not need to be cast.

1, drawing inclination: In order to be able to smoothly remove the shape from the sand mold, the steel casting factory will increase the slope on the surface of the shape in the parallel drawing direction, this process is called drawing inclination, the size of drawing inclination mainly depends on the height of the shape, the shape of the material and the modeling method and so on.

2, shrinkage rate: because of the linear shrinkage of the alloy, the size of the casting after cooling will be slightly smaller than the size in the cavity, in order to ensure that the casting can get the size it should have, the size of the pattern must be larger than the shrinkage of the alloy.

3, core head: the size of the core head should also be controlled, which has a great impact on the manufacturability and stability of the core assembly.