Why does the polishing zinc alloy die casting in the die casting plant have sand holes?

Release time:2023-10-06

Why does the polishing zinc alloy die casting in the die casting plant have sand holes?

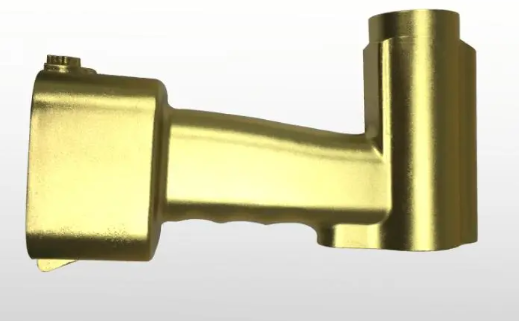

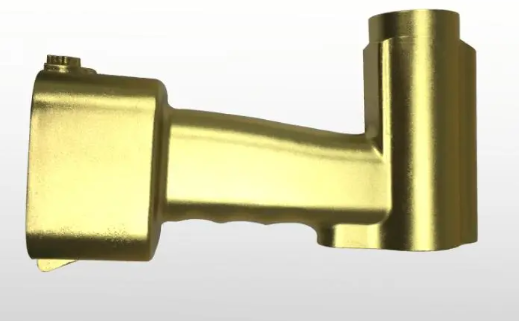

The performance of zinc alloy die-casting parts is very good, and generally there will be no problems. When the die-casting factory is doing the polishing of zinc alloy, it is found that there are sand holes on the zinc alloy die-casting parts. What are the reasons for the sand holes?

The appearance of sand holes in the die casting may be due to the water marks and bubbles produced by the die casting, and the surface of the zinc alloy die casting has a thin protective layer as long as 1-2mm, assuming that it is a thin water marks, which can be thrown off when polishing; Assuming that the water lines are serious or there are bubbles, sandholes will appear when polishing, because the protective layer has now penetrated, this place is hollow, and sandholes will appear once polished.

Therefore, the appearance of sand holes during polishing is because of the formation of water marks and bubbles on the surface of zinc alloy die casting, so why do zinc alloy die casting pieces produce water marks and bubbles?

(1) If the speed of the metal liquid entering the cavity is too slow, water marks will be produced, and the speed is determined by the injection force and flow rate. If the speed is too slow, the temperature difference between the metal liquid entering the cavity is too large, and it cannot be fused together, and water marks will be produced at the intersection;

(2) the mold cavity temperature is too low will also produce water marks, but too high will produce other problems, the furnace temperature is best maintained between 420-435 degrees, different product mold temperature will be different;

(3) The mold design is not reasonable, such as the cross runner is to control the direction of metal liquid activity, assuming that the design is not reasonable may produce metal liquid sputtering, resulting in water lines and bubbles in the die casting.