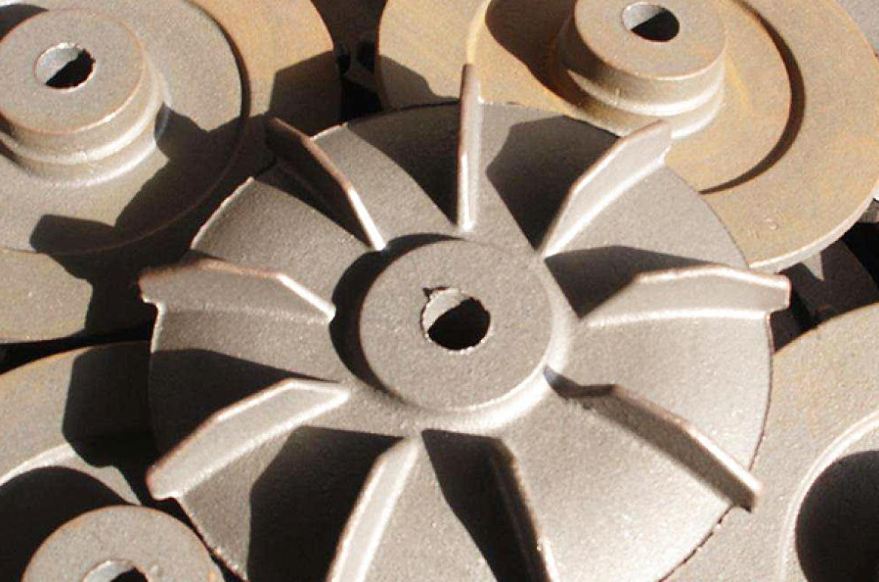

Casting parts - Defects of sand casting parts

Release time:2023-10-14

The defects of sand casting are: cold isolation, lack of pouring, porosity, sand adhesion, sand clamping, sand hole, sand swelling and so on.

1) Lack of cold preservation and pouring.

The filling ability of metal liquid is lacking, or the filling condition is few. Before the cavity is filled, the liquid metal will stop flowing, which will cause the casting to lack of pouring or cold insulation defects. When pouring, it will make the casting unable to obtain a complete shape. Although the casting can obtain a complete shape during the cold closing process, the mechanical properties of the casting are seriously damaged due to the existence of incomplete fusion joints. Prevent pouring and cold sealing: improve pouring temperature and pouring speed.

2-hole

A porous defect in a casting that occurs when the gas does not escape immediately before the liquid metal is crusted. The inner wall of stomata is smooth, dull or slightly oxidized. After the porosity in the casting, the exact bearing area will be reduced, causing stress concentration around the porosity, thereby reducing the impact resistance and fatigue resistance of the casting. Pores can also reduce the density of castings, making some castings that require water pressure tests scrapped. In addition, the porosity also has a favorable effect on the corrosion resistance and heat resistance of the casting. Prevent the formation of pores: reduce the gas content in the metal liquid, increase the permeability of the sand mold, and add an air outlet at the highest point of the cavity.

3 Glue sand.

The surface of the casting is attached with a layer of sand that is difficult to remove, which is called sticky sand. Sticky sand not only affects the appearance of castings, but also increases the workload of cleaning and cutting castings, and even affects the life of the machine. For example, when the surface of the cast tooth has sticky sand, it is difficult to be damaged. If there is sticky sand in machine parts such as pumps or engines, it will affect the flow of fluids such as fuel, gas, lubricating oil and cooling water, and will clean and wear the entire machine. Prevent sticky sand: add pulverized coal into the molding sand, and coat the surface of the mold with anti-sticky sand paint.

4) Sand

When casting thick small flat castings with wet mold, the surface of the castings is very difficult to produce grooves, scars and other defects.

Sand inclusions in castings are mostly in contact with the surface above the sand mold. Affected by radiant heat of molten metal, the upper surface of the cavity is difficult to arch and warp. When warped sand layers are continuously washed by molten metal streams, they may fracture, shatter, remain in place, or be carried elsewhere. The smaller the upper surface of the casting, the smaller the volume expansion of the molding sand, and the smaller the tendency to form sand inclusion.

5) Trachoma is a hole-like defect filled with molding sand on the outside or surface of the casting.

6) When sand casting is under the pressure of molten metal, the mold wall moves, and the casting local expansion forms a defect. In order to prevent the expansion of the sand, the strength of the sand mold and the rigidity of the sand box should be increased, and the pressure or fastening force of the box should be increased when the box is closed, and the pouring temperature should be properly reduced to make the molten metal surface encrust early to reduce the impact of the molten metal on the mold. Stress.